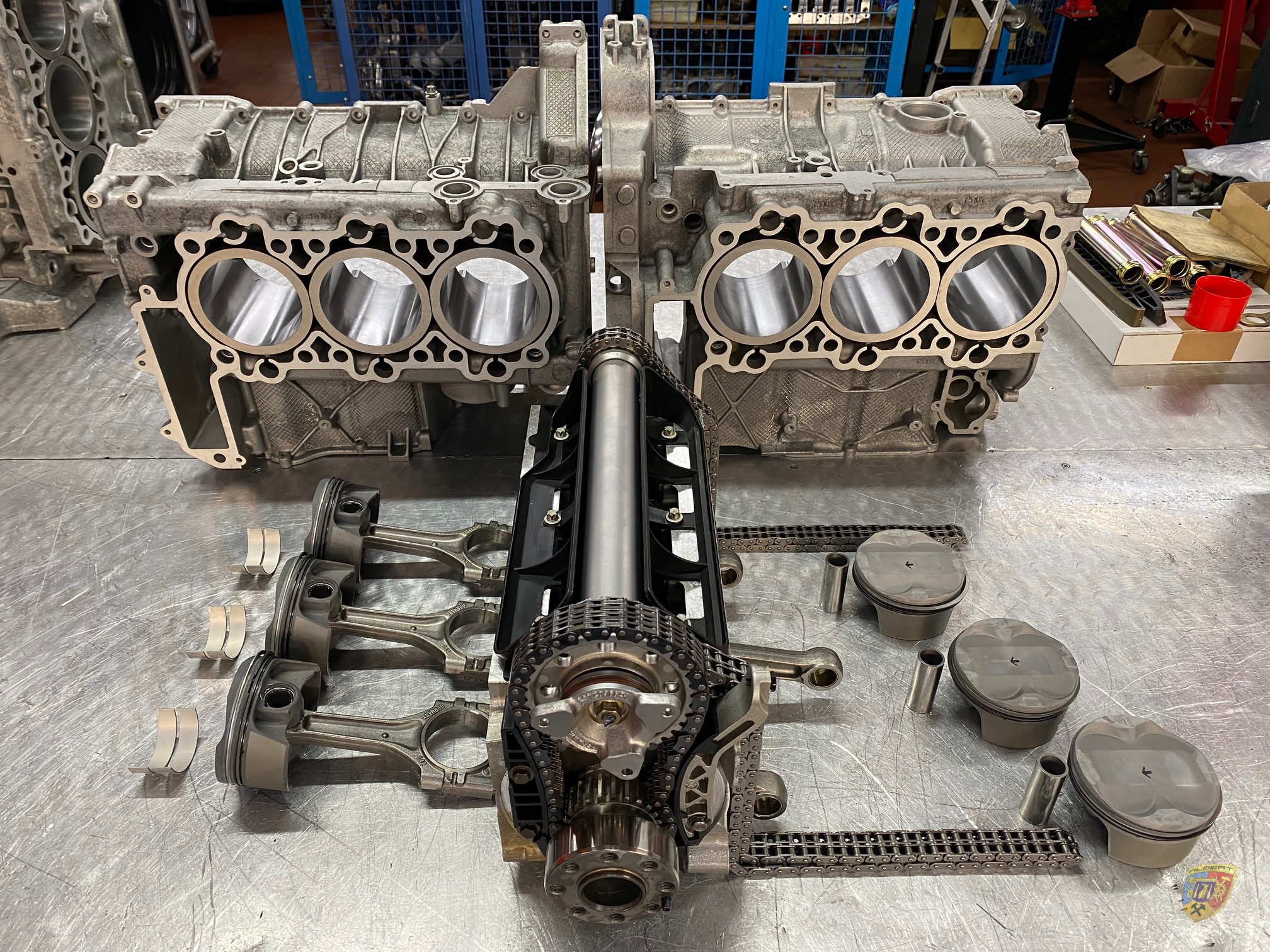

Albert Motorsport has been building stable Porsche Wasserboxer engines for over 20 years

based on stable nodular graphite cylinders and high-quality Mahle forged pistons.

Our complaint rate and damage rate has so far been: 0.00%!

In plain language:

With the more than 1,600 delivered engines, there is not a single damage!

Many of our remanufactured engines have now clocked well over 200,000km

and will run another tens of thousands more.

Should damage actually occur, our cylinders can be replaced one after the other

like in a Porsche-Mezger engine.

It is now considered a mark of quality on the market and in the Porsche scene

to have one of our Porsche engines installed.

Because our engines are solid and durable because they

are designed to last for decades and not at a cheap price!

From 2020 on we are using even better material for our revisions:

Chrome molybdenum cylinder with flake graphite!

Why are we doing this?

We only supply our customers with the best technical solutions for Porsche engine construction and we know that

chrome-molybdenum cylinders with lamellar graphite have even better material properties than the already very good

nodular graphite of our previous cylinders!

Why is this change only now?

We are constantly optimizing our materials and components. These innovations are the result of our further developments.

We will provide you with the best technically feasible quality for the Porsche engines that we have built perfectly.

The best feasible quality means what?

What we install in your Porsche has been previously tested by us on the race track under extreme conditions!

Our cylinders have been fitted to test engines in our own racing cars and subjected to high temperaturezones that no

normal Porsche driver will ever enter.

I also spent a lot of money in an engine lab to find the optimal installation tolerances of the various to identify materials.

All expansion coefficients of our components fit perfectly in all temperature zones.

Only then did I determine the installation parameters for our CNC center. The milling work is carried out on the 1/100

mm precisely executed for us. We want you to have many friends with our technology for your Porsche over the years.

So why chrome molybdenum steel with flake graphite instead of nodular graphite?

The advantages of Cr Mo with flake graphite compared to nodular graphite are unmistakable, that's why we do it!

THE ADVANTAGES ARE THE FOLLOWING:

- A significantly better heat dissipation

- A significantly higher abrasion stability

- A significantly higher pressure & tensile strength

- A significantly higher heat stability

- Better chemical properties

- Better mechanical properties

- Better running surfaces due to lamellar graphite

- Significantly less friction during operation

- Significantly better emergency running properties without oil

- Advantages in the area of lower corrosion

With this innovation, we are once again increasing the longevity of our Porsche engines.

This means that we are once again increasing the gap to our competitors in terms of quality!

The new cylinders for our Porsche Wasserboxer

engines are made of chrome-molybdenum steel

We know that we are not one of the cheapest providers in terms of costs.

20% of all our engine orders are due to complaints, complaints and botched

engines from low-cost suppliers.

Do not take any risks!

Don't let the butcher fix your car's heart!

Trust in the competence of our master surgeons, who will repair your Porsche

optimally, as if it were your own heart.

I'm happy to answer questions!

Best regards

Jürgen Albert

master mechanic